charpy impact test material standards|charpy impact cheat sheet : broker CHARPY IMPACT TEST ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy . WEB11 de dez. de 2023 · Step 2: Pick up the Powder and Tap Off Any Excess. Dee Mills / Byrdie. Before you go in on your face, you'll want to tap the brush on the side of the container to remove any excess. “Tapping your brush before applying powder helps prevent using too much product," says Nguyen. "If you apply too much powder, it can accentuate .

{plog:ftitle_list}

webAprenda a tocar Único, uma canção de amor de Fernandinho, no violão. Veja a cifra, a letra e o vídeo com a performance ao vivo.

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

Metallic materials — Charpy pendulum impact test — Part 1: Test method 1 Scope This part of ISO 148 specifies the Charpy (V-notch and U-notch) pendulum impact test method for .CHARPY IMPACT TEST ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod. For the test, a notched metal specimen is broken in half using a pendulum hammer.

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .

charpy test sample dimensions

charpy impact test standard pdf

ISO 148-1:2016 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. . The standard Charpy .IS 1757 (1988): Method for charpy impact test (V notch) for metallic material [MTD 3: Mechanical Testing of Metals] IS : 1757 - 1908 UDC 520’173’74&669’13 ( Third Reprint APRIL 1998 ) ( Reaffirmed 1 gg4 ) Indian Standard METHOD FOR CHARPY IMPACT TEST (V-NOTCH) ON METALLIC MATERIAL ( Second .

An impact test is used to determine a material’s impact strength, or the material’s ability to resist deformation when subjected to a sudden shock or impulse load. Learn more about it here. . is used to determine Charpy . The NIST Charpy Machine Verification Program is introducing certified low-energy and high-energy Charpy specimens to be tested at 21 °C instead of -40 °C.These new Standard Reference Materials can be ordered from the NIST SRM store (https://shop.nist.gov/) using the following numbers:Low-energy: SRM 2561 (NIST-Verification, 21 °C, 8 mm strikers), 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .

A decade before an iceberg shattered the hull plates of the Titanic and half a century before a plague of brittle fractures started sinking Liberty ships during World War II, scientists in the United States and France had devised a novel, and strikingly simple, method for measuring the way metal reacts to impact.. Today, that method, with some upgrades and .Standards • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials Purpose . translates into the toughness of the material. Equipment and Materials • Charpy V-notch impact testing machine (figure 1.3.1) • Specimens: 1018 CR steel & 6061-T6 aluminum • Thermometer • Water • Dry ice • Hot plate • Oven .

charpy impact test specimen size

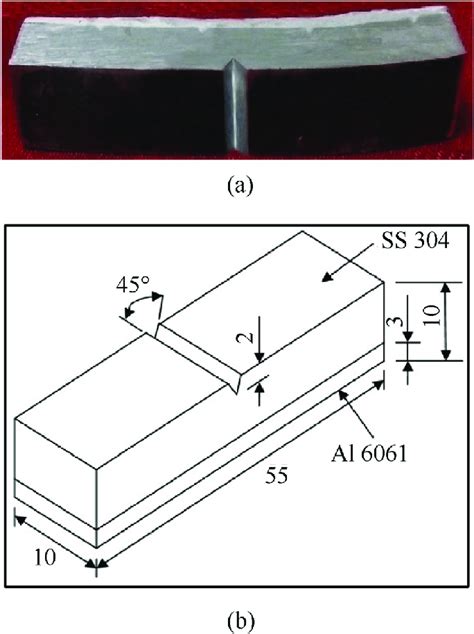

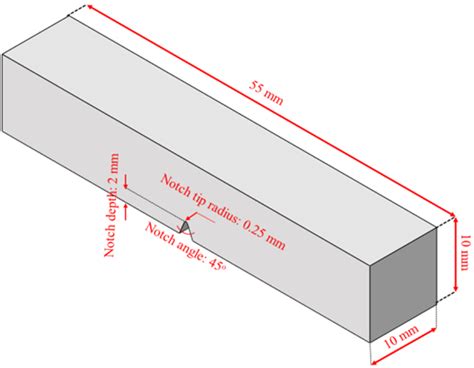

.the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of different applications on a daily basis are subjected to fluctuating temperatures, and since the fracture or failure behavior also depends .Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .

What Is the Charpy Impact Test? The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized sample with a V-notch machined into it. See Figure 1 below: 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .Charpy Impact Test ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken.The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials

Fogging Testing importing

Metallic materials — Charpy pendulum impact test — Part 1: Test method 1 Scope This part of ISO 148 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 does not cover instrumented impact testing, which is specified in ISO 14556.Explore the Charpy impact test method for metallic materials as specified by the European EN 10045 standard. Understand the test's purpose, procedure, and the significance of the energy absorbed in joules. Learn about the .CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values recorded can be used for qualityThe Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic .

Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead .ISO 148-1:2016 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 does not cover instrumented impact testing, which is specified in ISO 14556.Plastics — Determination of Charpy impact properties — Part 1: Non-instrumented impact test . and is more suitable for the testing of materials showing interlaminar shear fracture or of materials exhibiting surface effects due to environmental factors. . This standard contributes to the following Sustainable Development Goal. 9 .

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2),Both methods characterize the impact strength of a material in very similar ways so that the results largely correlate. The Izod test method, in which the specimen is positioned vertically, is normally used in ASTM standards.; The Charpy impact test, which uses a three-point bending arrangement, is the preferred method in ISO standards.; Both methods are used to measure .

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus This test determines the amount of .Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).How is the Charpy Impact Test performed? In a Charpy impact test, a notched (U-notch, V-notch, and double notched) material specimen is clamped in a test apparatus, and a pendulum is released to strike the notched area. The energy the material absorbs before its fracture is measured, indicating its impact strength.Engineers and researchers who have specialized Charpy testing needs will be the primary users of two new standards recently approved by ASTM International Committee E28 on Mechanical Testing. The new standards, E2248, Test Method for Impact Testing of Miniaturized Charpy V-Notch Specimens, and E2298, Test Method for Instrumented Impact Testing of Metallic .

The Charpy V-notch-CVN impact test also known as the Charpy V- notch test, is a standard test used to measure the impact energy (also referred to as notch toughness) absorbed by a material during fracture. The notch provides a point of stress concentration within the specimen and improves the reproducibility of the results.

charpy impact test specimen

WEBNo Globoplay você assiste TV Globo AO VIVO! Acesse e confira todos os momentos.

charpy impact test material standards|charpy impact cheat sheet